Under normal operating conditions and providing the system is installed correctly, it should last the lifetime of the appliance, which normally is 10 years. Prima Smooth carries a 10 year conditional guarantee. The conditions are that the system is:

- Correctly sized and installed in accordance with the manufacturer’s instructions, current Building Regulations and relevant British and European standards.

- Maintained correctly by a qualified and competent person and maintenance records kept updated for both appliance and system chimney.

- used in combination with an appliance burning only approved fuels in accordance with Schiedel Chimney Systems and the appliance manufacturer’s instructions.

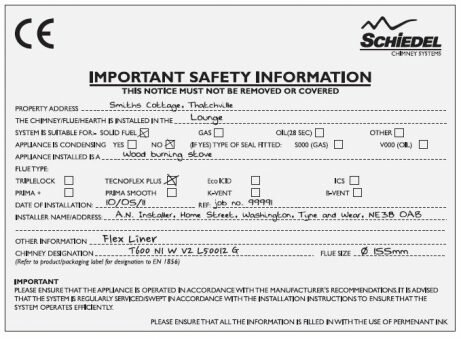

- The product registration form must have been filled in by an appropriately qualified installer (see p.3 for details), and returned to Schiedel Chimney Systems Ltd.

For recommended fuels listings, please refer to the HETAS Guide www.hetas.co.uk

In the event of a fault developing in the product due to defective materials or faulty manufacture Schiedel Chimney Systems undertake to replace the product only. Schiedel Chimney Systems cannot accept liability nor take any responsibility for the installation, building or redecorating costs or any other consequential losses arising. If any complaint is found to be a result of faulty installation, non-compliance with or abuse contrary to these conditions, the cost of site investigation is chargeable.