Whether powder coating, melting or forging - without process heat, technical processes such as the activities just mentioned would not be solvable in industry. Process heat is the thermal energy used in industrial processes. This is further subdivided into the use or dissipation of this heat, which is released during processes. Among other things, process heat can be used for heating rollers, melting metals, powder coating, deep fryers and much more. In the process, every company faces many questions and challenges:

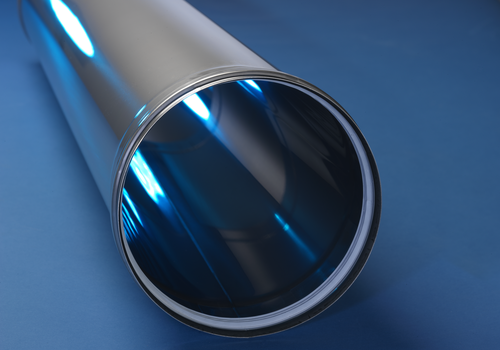

With Schiedel air flue systems, you are relying on future-proof and high-quality systems for energy-efficient use or dissipation of process heat. Our modern stainless steel systems offer a wide range of benefits. Depending on your requirements and needs, we have summarized a selection of stainless steel systems.

A single-wall, modular exhaust air and exhaust gas system - universally applicable.

A high pressure exhaust system for negative / positive pressure applications.