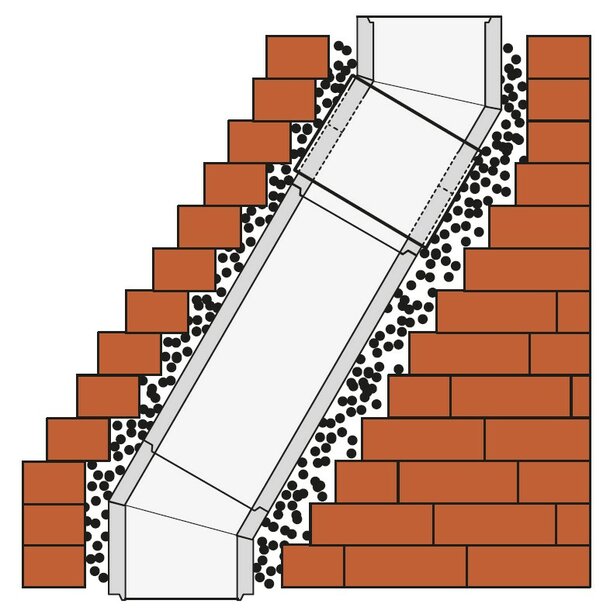

You must provide adequate clearance from combustible material in accordance with local Building Regulations. Combustible materials must be 200mm from the inner surface of flue liner or 40mm from the outside of the masonry chimney unless it is a floorboard, skirting board, dado or picture rail, mantel-shelf or architrave.

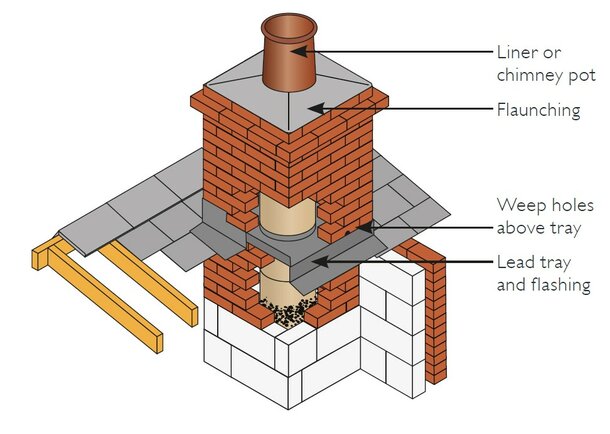

Fit appropriate lead dpc’s and flashings in accordance with the relevant regulations. It is recommend that the lead tray should be dressed up the outside of the flue liners to avoid a weak joint. Weep holes should be provided above the tray for moisture drainage.

Terminate the chimney to the correct height in accordance with local Building Regulations. The chimney can be finished by flaunching (1:3 cement/sharp sand) around a suitable chimney pot. Approved rain caps can be used to help prevent water entering the flue.