Chimneys are a critical part of building a resilient data centre.They allow the back- up generators to function properly in the event of a mains outage, keeping servers powered and important digital services available to the millions of users seeking to access them.

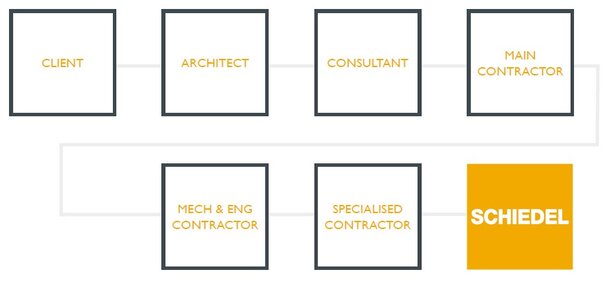

But flues are not just important to the building owner or operator; they also have a direct impact on the construction of new data halls.There are hundreds of contractors involved in a typical project, and each will require certain phases to complete before they can begin work on site. Leaving flues to the last moment – as some do – significantly raises the chance of errors just as the building is nearing completion.This will not only delay sign off and payment but will also damage the developer’s standing in a market where work is often awarded on recommendation. This oversight is the ‘chimney blind spot’.

Flues should be considered central to any robust uptime strategy and treated as an important step in guaranteeing availability more than 99% of the time. Data centre operators, for example, can only achieve Tier IV – the highest classification from the Uptime Institute – if a facility demonstrates a sufficient degree of ‘fault tolerance’. This means the effects of a power cut, equipment failure or interruption to the distribution path have to be managed long before any IT infrastructure is taken offline or, worse still, damaged.

It’s not difficult to see where chimneys fit in with the idea of fault tolerance.They will expel the back-up generator’s fumes and ensure any heat created is directed upwards, in turn lowering the risk of unexpected failure when on-site power is required. In this sense, they are part of the first line of defence when the mains are cut.

75 years’ experience in flue design and manufacturing

Selling into both commercial and domestic markets

Successful installations in key data centre locations across Europe

Notable customers include: Equinix, Wellcome Trust, Bunhill 2 Energy Centre, Zurich Data Centre

Despite this link, flues are often treated as an afterthought during the design and construction phase of a new data centre. Some see them as a specialism – which often leads to delayed installation or even a total refit later on – while others choose to keep costs low by opting for the cheapest product. This is a mistake because a facility will only be as resilient as its weakest point, regardless of whether a component is used every day or only when an emergency hits. Operators ultimately need to know their reserve system is going to work when it’s needed most.

Using the insights of Schiedel’s team of experts, this paper seeks to remedy industry’s chimney blind spot by promoting a ‘flue first’ mindset. It looks at the different industry factors that now make correct specification more important than before, the key points and timings for contractors and architects to consider, and a clearer understanding of what a successful installation looks like.

In doing so, Schiedel can better support those involved with data centre development during the most critical stages of a build. Setting out the argument in this way will also help to standardise the use of flues in data centres – especially important given the sector’s continued growth.

Flues perform a simple task in data centres. They are pieces of pipework or duct that expel gases and hot air from a generator’s combustion chamber to the open air outside. But this simplicity underplays their critical role when things go awry.

If the chimneys fail, there’s a high chance the on- site power will overheat or malfunction. This leaves servers without power in the event of a mains cut, which is often prohibitively expensive. Research has shown the cost incurred by major data centre outages continues to rise, with some estimates placing the figure at £4,500 per minute. However, this is based on data from 2019, so the number has likely risen further in the intervening years.

But it’s not just during operation that chimneys need to be considered. They also have a direct impact on the progression of a new build. Failure to specify

the correct product at the right time will usually lead to delays, either during construction itself or when commissioning is taking place. Delays are common on most construction sites, though they are particularly troublesome for data centre projects – to such a degree, in fact, that the Uptime Institute recommends some businesses write penalty clauses into contracts before work begins. These can be substantial when compared with the original awarded contract.

There are also retention clauses to consider, which typically range between 10% and 20% of the contract’s total value. These are included for claims made against installed products. While standard practice, any questions around product quality and suitability will typically result in payments being withheld or charges applied.

Beyond this, there are also reputations on the line. Mistakes could have repercussions that last long after any remedial work has taken place. Operators will be less inclined to employ a business again if the product originally specified is incorrect and in need of a refit.This creates added hassle and expense that is avoidable when the appropriate solution is chosen first time. Poorly designed flues can also pose a safety hazard to staff and the general public if they are unable to expel exhaust fumes properly – this issue is particularly important for builds close to built-up areas.

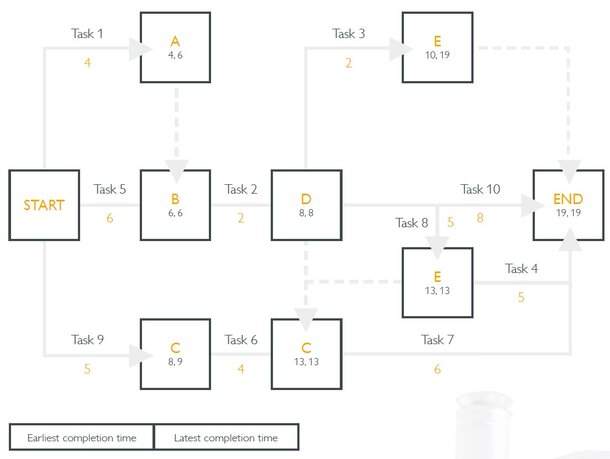

Introducing a flue at the right time is key given the penalty clauses that can be issued when a project is delayed. However, the tendency for contractors to leave the process until

the tender stage is an error, as the most successful projects invariably seek specialist opinion much earlier on (see section III).This approach provides more time but it also anticipates technical challenges long before the customer takes ownership.

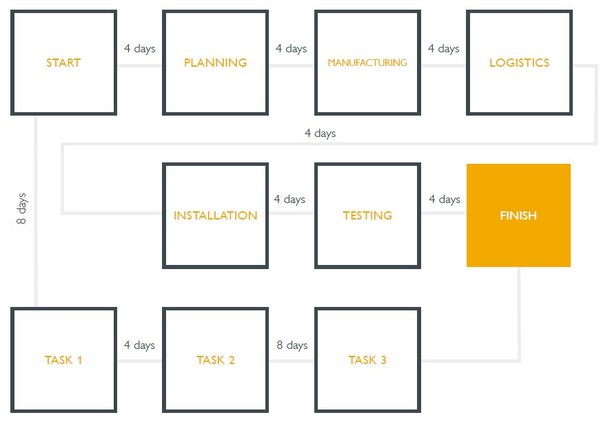

As a chimney specialist that has worked extensively in the data centre market, Schiedel advocates a ‘critical path’ method. Adhering to this process not only eliminates issues before they affect a build, but also ensures expertise is introduced at the most effective point.

“The total cost for a data centre project typically runs into the millions, with fitted assets that cost hundreds of thousands, so it makes little sense to leave a relatively inexpensive component to the last moment. “

Delays mean penalties but they can also threaten sensitive IT equipment when it has to be placed into storage.

Volatile energy supplies highlight the need for robust built assets in data centres. Equinix and Digital Realty Trust, the industry’s two biggest providers, have both

bought extra shipments of diesel as a precautionary measure in case of blackouts. Relying on back-up generators, however, will only be effective if the supporting system behind it works seamlessly in the event of failure.

Schiedel’s critical path has been designed to simplify flue installation in large non-commercial projects like data centres. By keeping these timings in mind, architects and project leads can minimise risk and guarantee a seamless process from design through to production, testing and installation.

Contractually agreed invoice and payment schedule

Reduced payment schedule as a result of delays, unexpected interruptions etc.

The critical path has a a number of advantages which are listed below.

By engaging a flue specialist at the correct point, problems are far less likely to occur on the installation date meaning less hassle for the project lead, architect and contractor.

Expert manufacturers know which stakeholders are most likely to impact on flue installation and can put measures in place so the project is seamless.

No unexpected problems when the flue arrives on site. It will be designed, built and delivered ready to fit.There have been instances when project leads have requested delivery of 600mm diameter flues in a week or less. Pipework of this size takes time to build and test properly, typically between four and 12 weeks.

Flue specialists like Schiedel can guarantee a level of performance that protects back- up power when it’s needed. This includes pressure testing for joints and an ability to withstand high temperatures throughout the product’s lifespan.

The appropriate flue will always be selected. Height and materials will be considered (factoring in issues like high winds) as well as sound attenuation when a data centre is found near a city or homes.

Planning/Tendering

Calculations

CAD Drawings

Quotation

Manufacturing

Quality Materials

CE Certifications

EI120 Fire ratings

Logistics

OTIF Deliveries

FORS Requirements

Special delivery requirements

Installation

Quality installation partners

Push fit system

No Bellows or sealant required

Testing

H1 Pressure tested

5000pa

TUV Certificated

Schiedel installed a generator exhaust system with Dieselec Thistle for a TJ Morris distribution centre in Amesbury, Wiltshire. The ICS 5000 system was used. From the generator silencer flange, the 500mm flue turns 180° running horizontally for roughly nine metres to connect to a 135° tee. The flue then rises vertically to around 11 metres, terminating with the offset around the building overhang. At the base of the system is 135° tee, with a support plate assembly, tee cap and drain connection underneath.

All pipework is horizontally supported with ceiling hangers and vertically with adjustable wall brackets and support plates. The ICS 5000 is a twin wall flue manufactured with a stainless-steel liner and case. It’s insulated with a 25mm thick high-density superwool blanket and is designed to accommodate pressures up to 5000Pa.

In partnership with Dale Power Solutions, Schiedel installed the ICS5000 flue system for RBS in Leicester. This project involved the use of a 38-metre truck-mounted MEWP to stretch to the work area.

Uni-strut framework was installed on the fire escape steel around the building’s staircase, which supported the exhaust flue riser. The framework clamped to the steel work and cantilever arms passed through at the open sections of the surround. These open sections were covered in bird mesh.

The flue ended with an open terminal, approximately 1-2 metres above the roof of the fire escape staircase. This project is a good example of Schiedel’s approach and efficiency in non-residential settings.

Schiedel was asked by Equinix to supply and assemble two exhaust runs for its facility in Zurich. The customer was supplied with the HP 5000, a twin wall flue manufactured with a 0.6mm/1mm thick 316-grade stainless steel liner and 304-grade stainless steel case. It is insulated with a 25mm/50mm thick high-density superwool blanket and is designed to operate under pressure up to 5000Pa (European Standard Designation H1). Operating with a continuous flue gas temperature up to 600°C (European Standard Designation T600). The system is also tested for thermal shock at 1000°C.

Schiedel worked with contractor Willis & Thornley to install five ICS 5000 flues at the Wellcome Genome Campus in Saffron Walden. They measured 400mm in diameter, with a 25mm cavity exhaust flue. This project is another good demonstration of the company’s abilities to work in non-residential settings with exacting requirements.

New-build data centres are complex projects involving potentially hundreds of different stakeholders. Given the scale of some builds, and the equipment and processes involved in bringing them to completion, it’s not surprising that flues have tended to fall down the agenda. Part of this is to do with their simple function, despite being one of the most important features when designing and developing a resilient facility.

Overlooking a flue system raises the chances of delaying a major project that runs to a strict schedule. When a new data centre is commissioned, the parent organisation expects to move in on the agreed date without any complication. Data is in huge demand and its availability directly impacts on the bottom line, so credible suppliers are highly desirable.

Schiedel’s critical path shows how to take the hassle out of flues. Bringing a specialist on board at the right moment will eliminate problems before they affect the timeline and will guarantee the right product is delivered and ready to work. If flues are deemed critical components – as this paper shows – then it’s incumbent on architects and contractors to work with a business that knows what success looks like. In a rapidly developing market, this is not just best practice but a competitive necessity.

An interesting project was for Equinix, who provide high secure data centres throughout the world.

The Wellcome Genome Campus homes some of the world’s advanced organisations in the field of genomics and computational biology.

Any commercial steel chimney or flueing system will always suffer from some sort of corrosion over time. The regular use of venting systems for heat and the scale of the developments means that maintenance needs to be regular.