Project details.

The project we undertook for them was with a mix of ICS and Prima Plus. The interesting aspect of this project was the additional request of making sure the flue was finished in “Oyster White”, to match the existing building.

Prima Plus is a single wall flue manufactured from high corrosion resistant stainless steel grade 316. With the addition of a silicone gasket fitted to the bead of the male spigot, it is designed for use with a new generation of condensing gas and oil appliances typically with continuous operation temperatures of up to 200°C and positive pressure up to 200 Pa at the appliance outlet.

Condensing flues systems tend to be subject to significant corrosion attack by condensation and flue gases. However, Prima Plus is specifically designed to resist corrosion for the longest possible flue life. It is the only stainless steel single wall flue system in the world to have passed the internationally recognised GASTEC corrosion test.

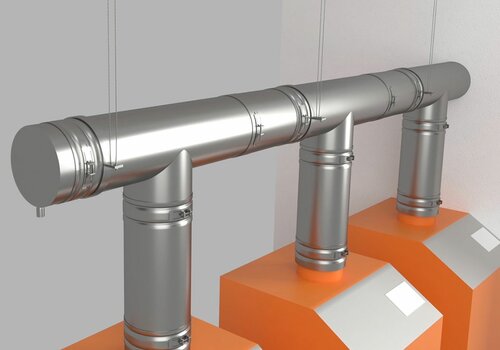

Two Prima Plus single wall flues with a 200mm ID were installed from two

Ideal Xtra 320Kw boilers, which rose up to connect into a 350mm ID single wall header. The header runs horizontally for approximately 3 metres, including two 90° bends and then connects into a 350mmID/400mmOD ICS Plus twin wall chimney.

ICS Plus is a twin wall flue manufactured with a stainless steel liner and stainless steel case. It is insulated with a 25mm thick high-density (128kg/m³) superwool blanket. Designed for pressure capability of 200 Pascal’s for use with semi and fully condensing appliances. Continuous Firing Temp of 160° C and Short Firing Temp of 200° C.

The ICS then continues the journey through the wall to the external wall, where the flue turns through 93°, including wall support and drain point. It rises 6m to termination. Also the external riser was installed using a scissor .The installation of the chimney system within the boiler room was achieved by means of a 2.3 meter high alloy scaffold tower, which was arranged by our

PASMA qualified operatives.

The final external finish was

RAL 1013 Oyster White as requested by the client. As you can see, the job was finished perfectly and provides a neat and fresh look to the chimney system.