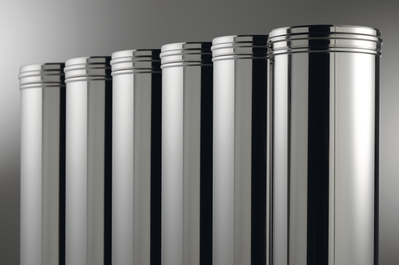

Our range of flue systems: mineral and steel for domestic and commercial, as well as our outdoor living products and our Defra exempt wood-burning stove systems.

We have loyalty schemes for installers, installation guides and videos for all our products and a superb technical team to advise on any pre-sales or post-sales queries.

Support for commercial and residential installations and product details.