INDUSTRIES - POWER GENERATION

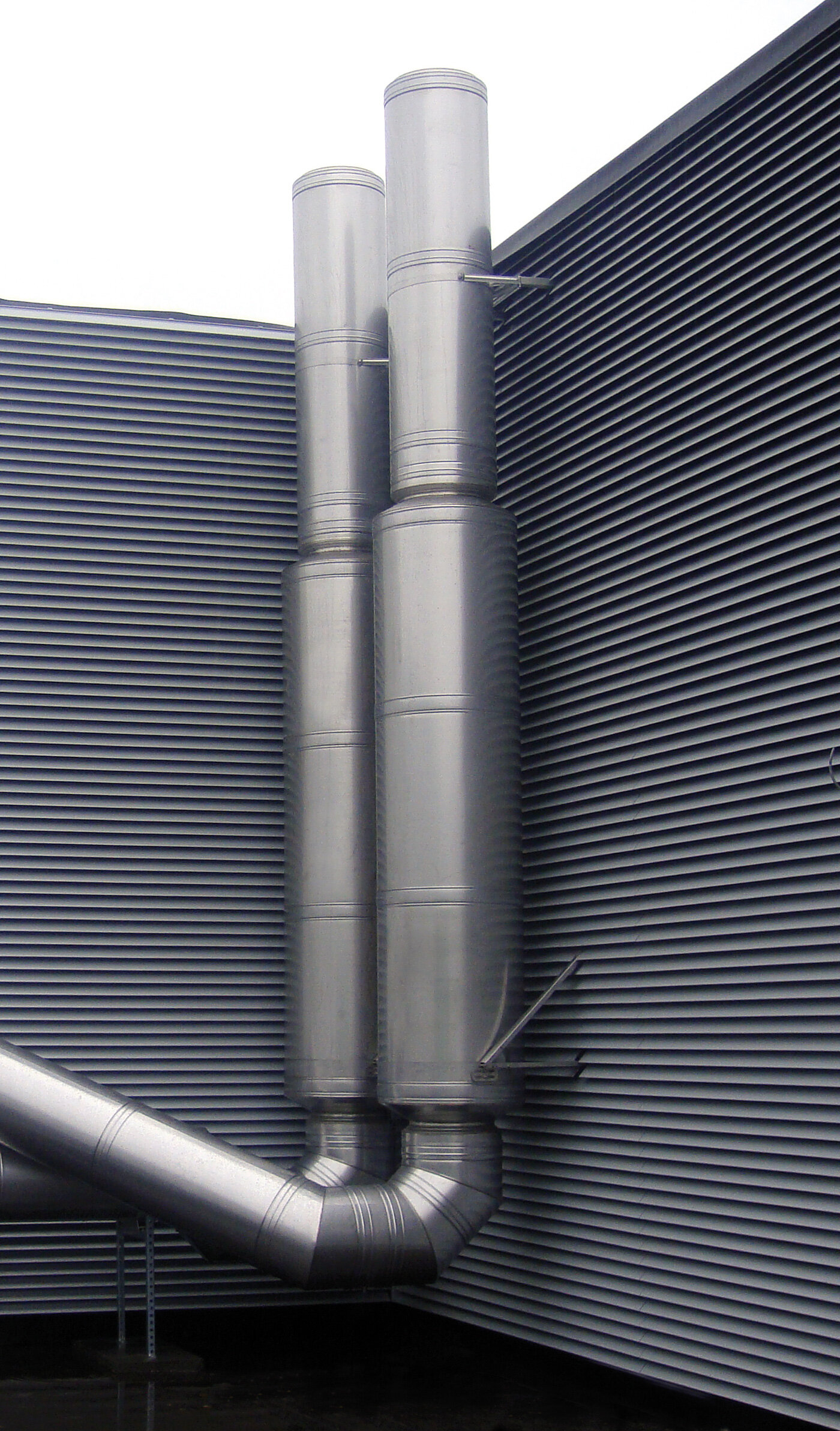

Make optimal use of the force and convert it into energy. As a manufacturer and supplier of gas and diesel engines, you want to get the maximum return from generator sets and CHP applications. This also includes proper disposal of gases and other emissions. While architects and building owners are not interested in exhausts and annoying installation processes. At Schiedel we can help you engineer the perfect exhaust solution!

Exhaust system for applications with positive pressure (5000 Pa) and high flue gas temperatures

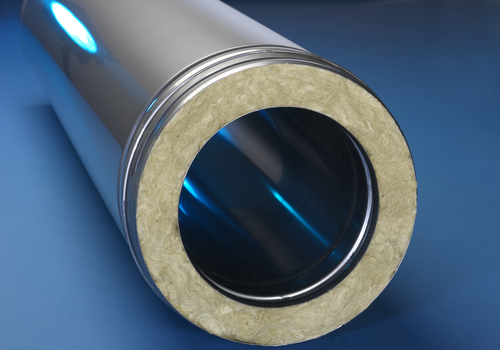

Dubbel- en enkelwandig systeem voor hoge en lage druk toepassingen.