Flexible liners are the best way to reline an existing chimney, something becoming more and more popular with the number of old, brick chimney fireplaces being opened up, combined with modern,

efficient stoves being installed, which tend to give off

much more heat in certain rooms in comparison to other methods of heating.

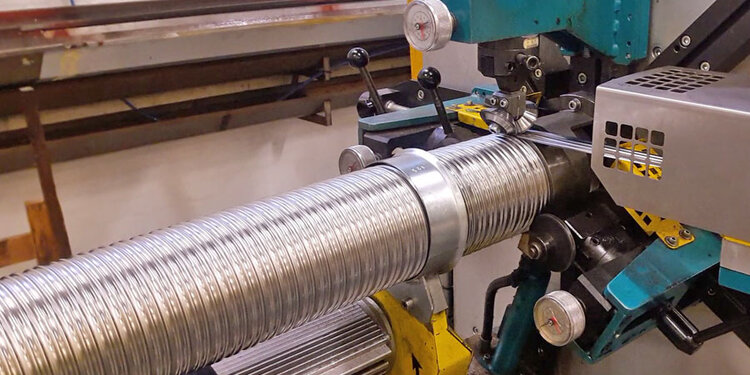

This brief video shows the production process in our Washington plant and shows the various steps involved in producing our

quality liner.

The strip of flex stainless steel is fed from main coil and is then fed through magazine. The magazine houses the profile form wheels which create the convolutions. When the material is fed round the mandril the strip overlaps, thus creating the flex liner.

As always, safety is of paramount importance, as proved by our recent awards for no

Lost Time Accidents and

World Class Awards. The operator is wearing all the correct PPE and makes safe the end of liner with masking tape as it it extremely sharp.

The operator feeds the liner through until it reaches the trough.

Once in the trough, the liner is marked at 1 metre intervals to satisfy EN1856-2 for traceability, The information includes work order number, date, diameter, chimney product designation: T600 N1 W V2 L50012 G 316L, T600 N1 W V2 L70012 G 904L & T600-N1-W-V2-L50012-G.

For Gasflex, the arrows indicate the direction of gas flow.

Once the length is complete, the operator makes other end safe with masking tape and then the flex liner is passed down ready to be coiled and packed off.

The liner is then secured to the mandril. During the coiling process, the bubble wrap is applied followed by shrink wrap, as well as, instruction manuals, product labels, etc.

The mandril arms released to enable the operator to remove finished flex pack and the fork lift driver collects finished flex pack and transports it to Flex Warehouse ready for our customers.

Contact us more information or visit the

TecnoFlex page for more technical details and brochure downloads.